The environmental aspects, the safety prevention and the Corporate Social Responsibility (CSR)

Environmental aspects : water, air, noise, waste, energy.

Environmental aspects

- Reduction of water consumption by 93% compared with 2001

- Ratio of water consumed per ton produced divided by four compared to 2001 (39.5 in 2001 and 9.8 in 2017)

- Biannual monitoring of groundwater by an independent contractor

- Discharge of waste water into public waste water treatment plant: 100% control by an external laboratory before disposal

- Periodic monitoring with measurements both internally (noise level in workshops and operator exposure) and externally (emissions outside the facility)

Solvent pumping station

Production automation

VOC decrease

| Solvent emissions (T) | of which chlorinated solvents (T) | |

|---|---|---|

| 2000 | 93 | 23 |

| 2006 | 47.5 | 1 |

| 2017 | 40.4 | 0 |

Outdoor tank

Hive for bees

- Audit of contractors for wastes disposal

- Reduction of waste production as well as non-value waste: quantity divided by three since 2006 per ton of manufactured product

- 25 different waste streams

Iron drums

Industrial piping

- Purchase of a high-efficiency compressor

- Installation of quick-opening doors

- Replacement of the laboratory boiler

- Changed investment in 2018 in a new burner for the factory boiler in order to reduce natural gas consumption as well as CO2 emissions

- Insulation of singular points (valves, flanges…)

- Photovoltaic cells implementation in December 2017 to save 5-6% of non-renewable electricity consumption

Photovoltaic cells

Safety prevention

Emergency equipment

- Sprinklers network and fire hose cabinets

- Fire extinguishing systems

- Emergency shutdowns in all workshops and tank-farm storage

- Fire protection by sprinklers on the whole site

Intervention capabilities

- Ongoing training of the fire brigade rescue team on site

- 3 safety exercise practice organized annually

Training

- 400 hours/year of environmental-health and safety training

- Safety management system

Industrial hygiene

Measures to control the working conditions on the whole site (exposure of the employees to the chemical risk, efficiency of the ventilations, noise, and lighting)

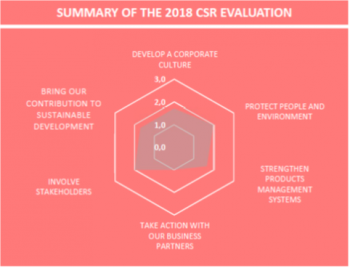

Corporate Social Responsibility (CSR)

- Signatory of the “Responsible Care” charter since 2006, the voluntary program of performances improvement and openness to stakeholders.

https://www.icca-chem.org/responsible-care-global-charter/

https://www.francechimie.fr/engagements-rse - Evaluation of its CSR approach relying on the Responsible Care repository “Cap to the CSR”.

- Definition of an action plan to strengthen its CSR approach, in particular on principle Nr4 “Acting with our business partners”.